Flanged Immersion Heater

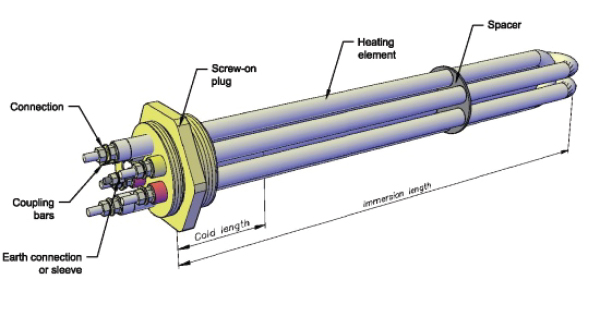

Screw in immersion electrical heaters are ideal for direct heating of liquids like water, oils, caustic solutions, chemical solutions, mild acids, glycol solutions, asphalt, vapour degreases, detergents, air and gas flow.

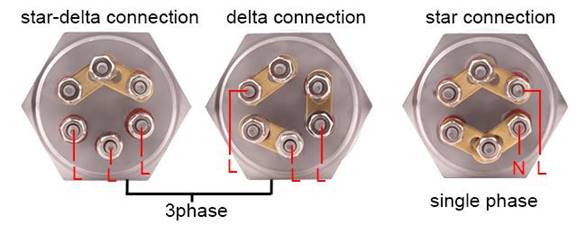

Available in a variety of sizes, heating element sheath materials and wattages, single phase or three phase to suit your requirements. Screw in Immersion heaters consist of hairpin bend round or FIREBAR flat tubular heating elements which are silver soldered or TIG welded into a BSP or NPT threaded brass or stainless steel screw fitting.

Terminal housing can be provided for electrical connections as well as options for thermostat, thermocouples, built in power control as well as pilot light to give visual indication of on or off status.

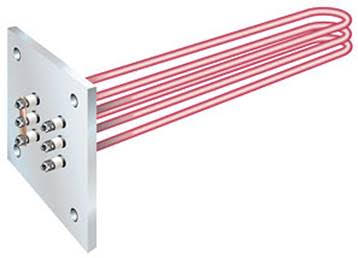

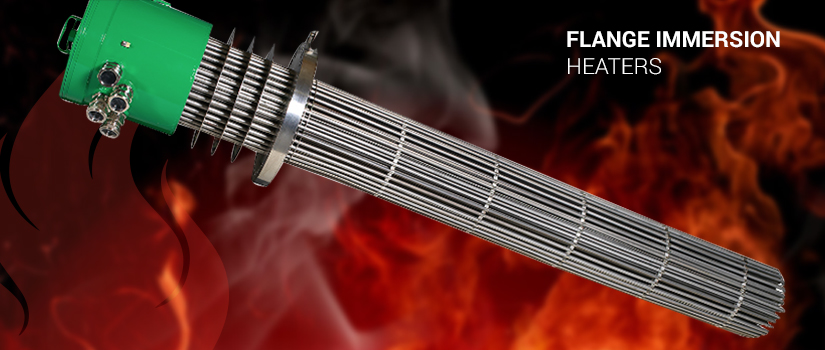

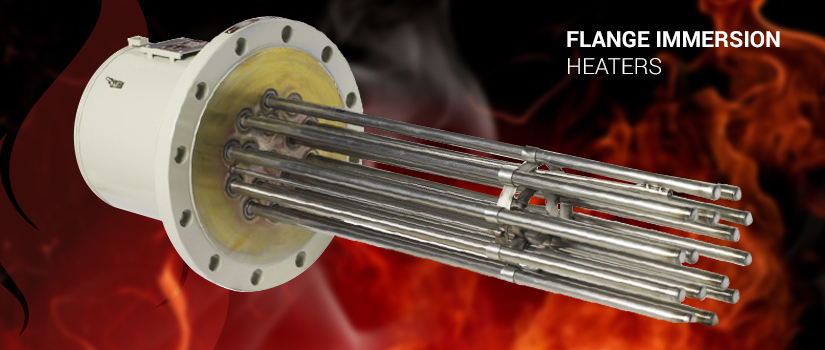

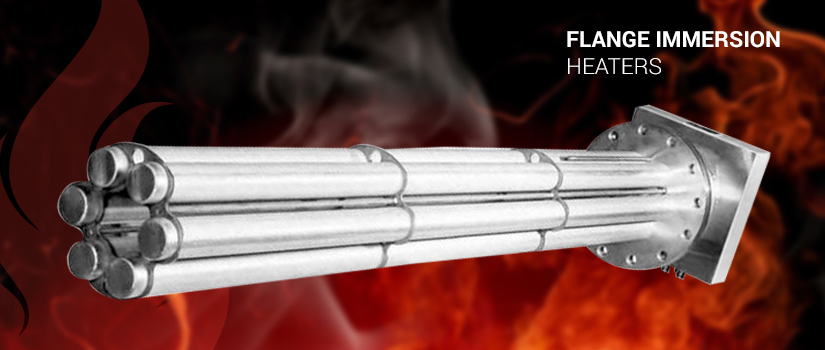

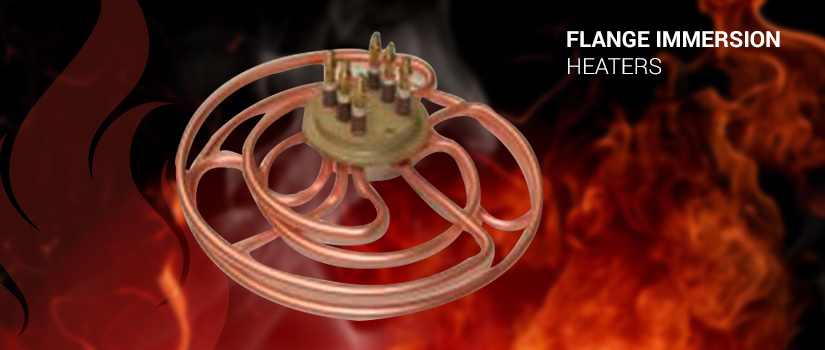

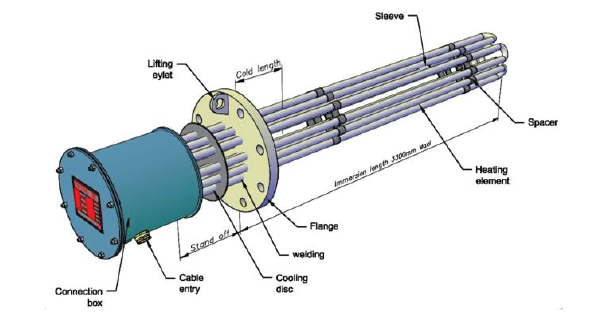

Process Flanged Immersion Heaters

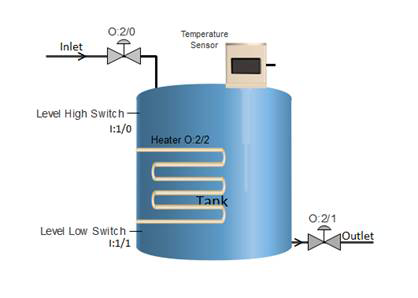

Flange immersion electrical heaters are ideal for applications requiring higher kilowatts and direct heating of liquids like industrial water rinse tanks, boiler equipment, hydraulic oils, crude oils, lubricating oils, caustic solutions, chemical solutions, mild acids, glycol solutions, asphalt, vapour degreases, detergents, air and gas flow.

Available in a variety of sizes, heating element sheath materials and wattages, single phase or three phases to suit your requirements. Process Immersion heaters consist of hairpin bend round or FIREBAR flat tubular elements which are silver soldered or TIG welded into a flange.

Standard element supports will be supplied for open tank or convection heating. For forced circulation applications, baffles can be provided to enhance flow and heat transfer.

Rubber, asbestos-free and spiral wound gaskets are available for all flange sizes.

Terminal housing can be provided for electrical connections as well as options for thermostat, thermocouples, built in power control as well as pilot light to give visual indication of on or off status.

Stand-off terminal housings can be provided to keep electrical termination area cool.

.jpg)

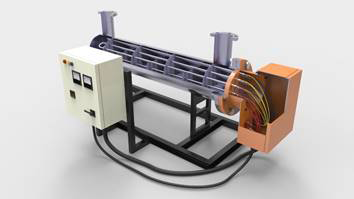

HSCO™ Pipe Heaters are especially constructed to fit inside standard 2 or 3” schedule 40 NPS pipes. These industrial tank heaters are specifically designed for usage in tanks that require extremely low watt densities such as waxes, thick liquids such as tar, molasses and corrosive mediums. HSCO pipe heaters do not come in contact with the liquid medium. Rather the indirect heating from element to pipe is used to heat liquid sources. This provides easy maintenance, as the tank does not need to be emptied out if the industrial heater needs to be replaced.

Designed to withstand high heat environments, HSCO pipe heaters are an excellent choice to use with heavy bunker fuel oils, corrosive liquids and liquids with high viscosity. HSCO pipe tank heaters can use flange heaters, screw plug heaters as well as resistance coil heaters (open coil heaters).

Pipe heaters use supportive ceramics resistant to high thermal heat that provide mechanical support to coils. Thermocouples can also be used to relay temperature readings to a digital controller that helps regulate the heat intensity. Steel pipes can be used for their thermal transfer properties and their corrosion resistant properties to many petrochemical solutions. Open coils are the most efficient type of electric heating while at the same time being the most economically feasible for most industrial heating applications.

HSCO also manufactures other industrial heating solutions such as band heaters, immersion heaters, circulation heaters and

Terminal Connection

THREADED FLANGE HEATER :- TECHNICAL DATA

IMMERSION FLANGE HEATER :- TECHNICAL DATA