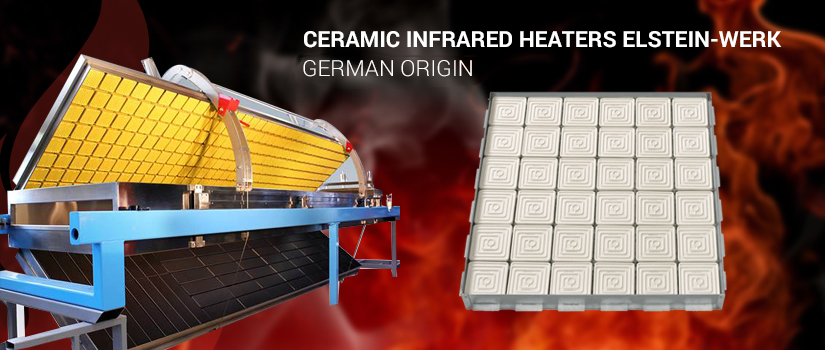

THE COMPNAY ELSTEIN-WERK WAS ESTABLISHED IN NORTHEIM 1950 AS THE ONLY FACTORY WORLDWIDE SPECIALISED IN MANUFACTURERING CERAMIC INFRARED RADIATORS.

APPLICATION for the use of INFRARED HEATERS / RADIATORS ARE;-

- HEATING PLASTIC FOILS and SHEETS IN THERMOFORMING MACHINES

- DRYING PLASTIC EMULSIONS, HEATING LAMINATED DRY RAW & PRINTED PAPERS, CARDBOARDS

- DRYING GLAZES ON CERAMIC TILES

- TEMPERING GLASS

- PRE-HEATING WELD SEAMS IN PIPE CONSTRUCTION

- PRE-HEATING PLASTIC PIPES FOR JOINING

- TEMPERING INJECTION MOULDINGS

KITCHEN CABINET TO KEEPING MEALS WARM, AND THE FILED COULD BE CONTINUED AD INFINITUM. This is because almost all industrial production, handling OR refining process INVOLVE drying OR heating tasks, and CERAMIC INFRARED RADIATORS can be solved outstandingly well using ELSTEIN-Products.

MEDICAL

Infrared heaters are commonly used in this field. Hospitals, clinics and medical institutions implement its effectiveness in separating platelets from the blood. Some manufacturers transform these heaters to compliment the needs of the sauna cabin industry. Because of their infrared heating, medical experts have declared them useful in neutralizing viruses and bugs (the modified technique of cleaning incubators hygienically- which was previously done by placing incubators in the sunshine).

Automotive

Infrared radiant heaters have influenced auto manufacturers to realize their benefits in the automotive panel manufacturing projects. Since the workable manufacturing areas was recessed and tight to work within, industrial heating solution manufacturers tried to simplify the problems in using adhesive materials. They designed a form of infrared radiant heating that is capable of drying and annealing two parts together in a shorter time period.

Mining/Oil/Gas

The mining, oil and gas industries have found the best ways to increase their productivity and allowed companies to enhance the quality of products they are manufacturing. They can now combine infrared and microwave heat to clean the oil laced sand from the crude oil tanks.

Construction/Manufacturing

Infrared radiant heaters can be used for creating construction materials that require demanding environments involving extreme temperatures and processing plants. They are helpful in binding different materials together so that something new and worth using can be created, which can satisfy both domestic and industrial needs.

Packaging

Infrared electrical heating elements are used to improve thermoforming efficiency to help companies accomplish numerous objectives. Manufacturers normally create complete systems having maximum control according to the market demands. They have incorporated different mechanisms that are capable of implementing infrared furnace and thermoforming techniques in several packaging tasks. The companies can save up to 40 percent of energy with these heaters and can achieve payback for retrofitting in six months.

Thermoforming

The plastic thermoforming industry is another place where, infrared radiant heaters are frequently used due to their ability of maximizing quality and efficiency of the companies. The heaters are known to reduce average expenses on thermoforming, thus affecting the profit margin of users up to 40 percent. They can also enhance the effectiveness of fixed capital assets as compared to spending millions on their replacement.