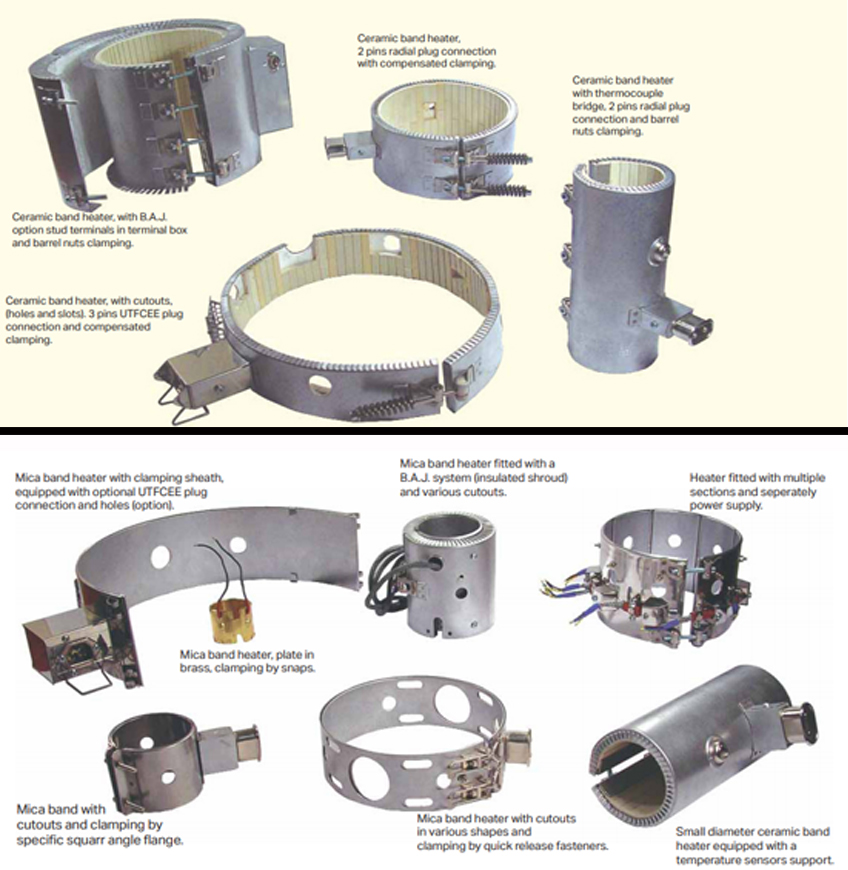

Examples for Special Band Heaters.

For best determining the parameters of this type of band heater, we kindly ask you to complete specifications. Non contractual pictures.

Assembly Recommendations for Band Heaters.

As for facilitating thermal transfer between the band heaters and the sheath, some supplementary cautions must be taken. For further information, please see our technical section for assembly instructions:

- We advise you to match the heater watt density to the medium being processed. A band heater too performant for your needs could increase not only the risk of overheating but also the switching frequency of the controller. Do not operate aboce rated voltage, watt density or temperatures. Excess voltage, wattage or temp. will result in heater failure.

- Our band heaters work by conduction heat transfer: They should never come into contact with the open air.

- Please avoid to open band heaters when mounting them up on the barrel:

irreversible internal damage could occur. If possible, they must be slipped over the end of the barrel. Only band heaters equipped with a hinge or ceramic band heaters can be opened.

- Band heaters and wirings must be protected from eventual material contamination as a measure to preserve their heating capacity. Prior to installation barrels should be cleaned.

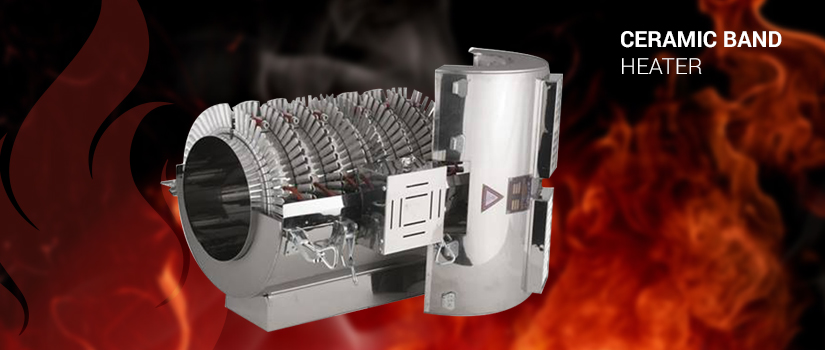

[HSCO- CBH] are Ceramic band heaters are typically used for injection molding, extrusion, and blow molding.

A high performance alternative to traditional mica band heaters. Ceramic band heaters are capable of operating at temperatures up to 1400°F with the ceramic fiber insulation providing excellent thermal efficiency. Ceramic band heaters can open fully for easy installation around the barrel. HSCO Ceramic Band Heaters feature a stainless-steel outer sheath for superior oxidation resistance. Also possible to incorporate holes / slots at any locations as desired at the time of placing the order: To